Let customers speak for us

Premium Epoxy Resin Australia

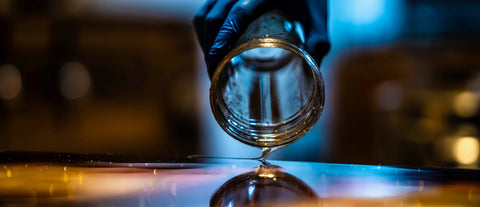

Experience the unparalleled quality and versatility of our Ultra Clear Epoxy Resin Kits and bring your creative visions to life with ease and confidence. Choose Clearpox for a flawless, durable, and beautiful finish every time.

Versatile

Clearpox ultra clear epoxy resin is the perfect choice for a wide range of projects. Whether you're creating intricate resin art, casting molds, or working on practical applications such as coating surfaces, this resin adapts seamlessly to your needs. From DIY crafts to large-scale industrial projects, Clearpox offers unparalleled flexibility, making it an essential tool for artists, hobbyists, and professionals alike.

Key Benefits

Built to endure, Clearpox epoxy resin is formulated for long-lasting performance. Its robust composition ensures that your creations will remain as beautiful and strong as the day they were made. This durability means you can trust Clearpox for projects that need to withstand wear and tear, providing peace of mind that your work will stand the test of time.

One of the standout features of Clearpox is its advanced non-yellowing formula. Unlike other resins that can discolour over time, Clearpox retains its pristine clarity, ensuring that your projects maintain their original brilliance. This makes it an ideal choice for preserving the aesthetic quality of art pieces, jewellery, and other creations that rely on a crystal clear finish.

Clearpox is designed to bond securely to a wide variety of surfaces, including wood, metal, glass, and more. This superior adhesion means you can use it confidently in diverse applications, knowing that it will stick firmly and provide a stable, reliable finish. Whether you are working on a delicate art project or a heavy-duty coating, Clearpox epoxy resin ensures a strong bond every time.

Perfect for both indoor and outdoor projects, Clearpox’s water-resistant properties make it incredibly versatile. It can be applied to damp surfaces without compromising its effectiveness, allowing for greater flexibility in your working conditions. This makes it an excellent choice for marine projects, outdoor furniture, and any other application where moisture exposure is a concern.

Clearpox epoxy resin is engineered to withstand chemical spills and exposure without breaking down. This chemical resistance makes it suitable for environments where other resins might fail, ensuring that your projects remain intact and unaffected by accidental spills. It's an ideal solution for laboratory countertops, industrial settings, and other areas where chemicals are frequently used.

Clearpox is incredibly user-friendly, making it accessible to everyone from complete beginners to seasoned professionals. Its straightforward mixing and application process allows you to achieve professional results with ease. The resin flows smoothly and cures consistently, ensuring that you can focus on your creative vision without worrying about technical difficulties.